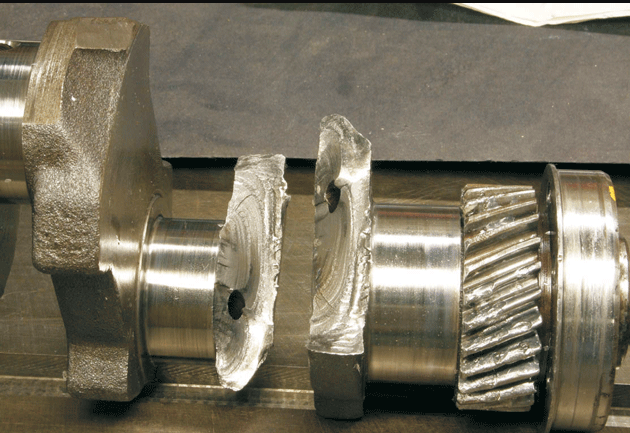

Failures Investigation

We’ve followed the official course ODA (Observe, Deduce, Analyze) run by international experts in aerospace failure investigations, with several decades of experience on aircraft crashes and catastrophic engine failures. A very valuable experience where real hardware was observed, and failure modes were suggested, before being told the official conclusions of the failure investigation.

We’ve also studied in detail iconic catastrophic failures which led to significantly increase the Engineering knowledge in fatigue, damage tolerance, plasticity, creep and aeroelasticity.

We’ve successfully led failure investigations of the following components:

excessive rotordynamic vibrations of a novel turbomachine shaft (oil&gas)

novel turbomachine shaft failure (oil&gas)

pressure vessels (oil&gas)

premature failure of bi-metal tensile specimens with seeded inclusion on the diffusion bonded surface (Aerospace)

micro-tube heat exchanger applied to Formula 1 car intercooler bench test (Automotive R&D)

buckling of very large hot pipes (oil&gas)

cracking of very expensive composite helmets (Aerospace)

eVTOL battery pack non compliance against required drop test (Aerospace R&D)

Our senior personnel was involved directly in the following high profile failure investigations, mainly in Rolls-Royce (Civil Aerospace):

Trent 900 catastrophic fan disc failure during spin test

Trent 1000 IP compressor blade off events

Trent 700 premature fan blade off events

Trent 900 catastrophic disc failure in-flight

Trent XWB 97k excessive fan blade vibrations

Trent XWB 84k excessive fan blade vibrations during a novel spin test

Unexpected bird strike penetration in wing (Lilium test)