Rotordynamics

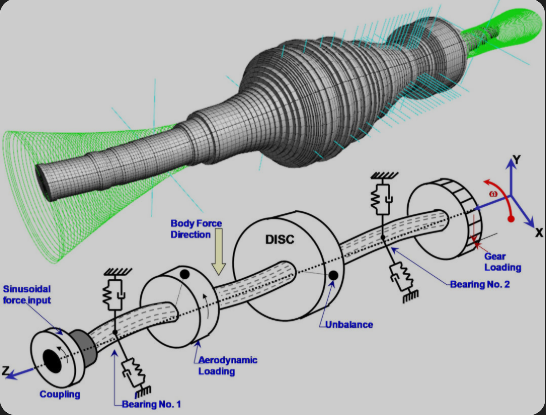

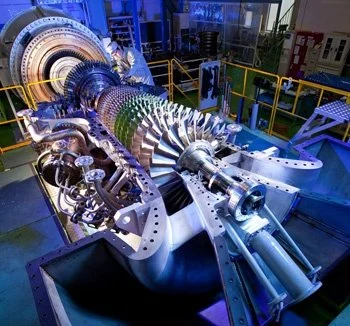

Our rotordynamics capabilities help clients ensure that rotating machinery such as turbines, compressors, pumps, and motors operate safely and efficiently under all operating conditions. We use advanced analytical tools and simulation techniques to predict and mitigate critical issues such as unbalance, instability, and resonance.

Our rotordynamic services include:

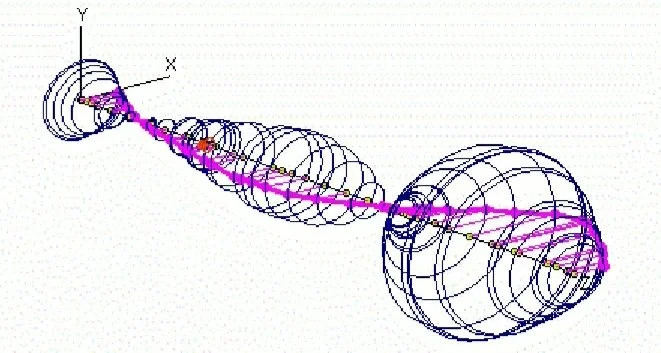

Critical Speed Analysis: We identify critical and near-critical speeds, ensuring safe separation margins across the operating range.

Unbalance Response Simulations: We evaluate how system stiffness, damping, and unbalance affect shaft vibration and bearing loads under dynamic excitation.

Stability and Whirl Predictions: We model fluid-induced instabilities, including oil-whirl and oil-whip effects in fluid-film bearings, and assess the risk of system divergence.

Torsional Vibration Analysis: We simulate torsional resonance and dynamic torque transmission to ensure coupling, gear, and shaft integrity.

API Standards Compliance: We generate rotordynamic reports that satisfy API 617, API 684, and ISO 10437 requirements, often mandatory for high-speed rotating equipment in oil & gas and power generation industries.

Our analyses help clients avoid costly downtime, extend equipment life, and design high-speed rotating systems that meet both performance and reliability targets.