NDT and Damage Tolerance

We provide end-to-end support in Non-Destructive Testing (NDT) and damage tolerance analysis to help clients manage structural integrity throughout a component’s operational life. Our approach integrates inspection data with advanced simulation and analytical techniques to support both in-service evaluations and new product qualifications.

Our capabilities include:

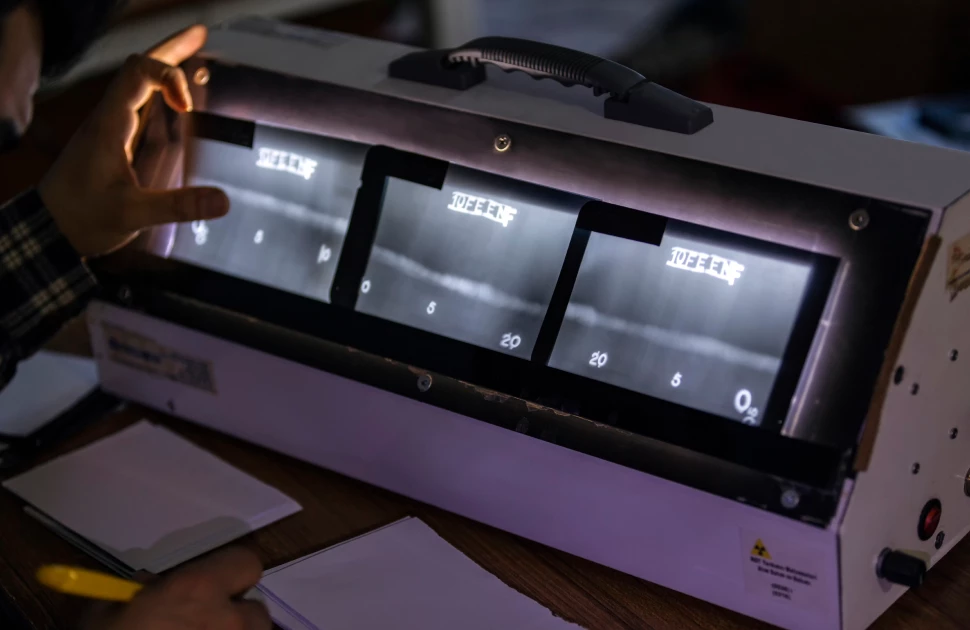

NDT Planning and Oversight: We help select the most appropriate NDT techniques—such as ultrasonic, radiographic, magnetic particle, eddy current, and dye penetrant—based on material type, geometry, and defect-criticality.

Interpretation and Engineering Correlation: We go beyond flaw detection by correlating NDT findings with stress fields, fatigue life predictions, and fracture mechanics results to understand the true impact of detected indications.

Damage Tolerance Analysis (DTA): Using fracture mechanics and fatigue crack growth models, we evaluate flaw propagation behavior under service loads to define safe inspection intervals, critical crack sizes, and residual life.

Compliance Support: We ensure full compliance with standards such as FAA, EASA, BS, ASTM, and industry-specific lifing philosophies.

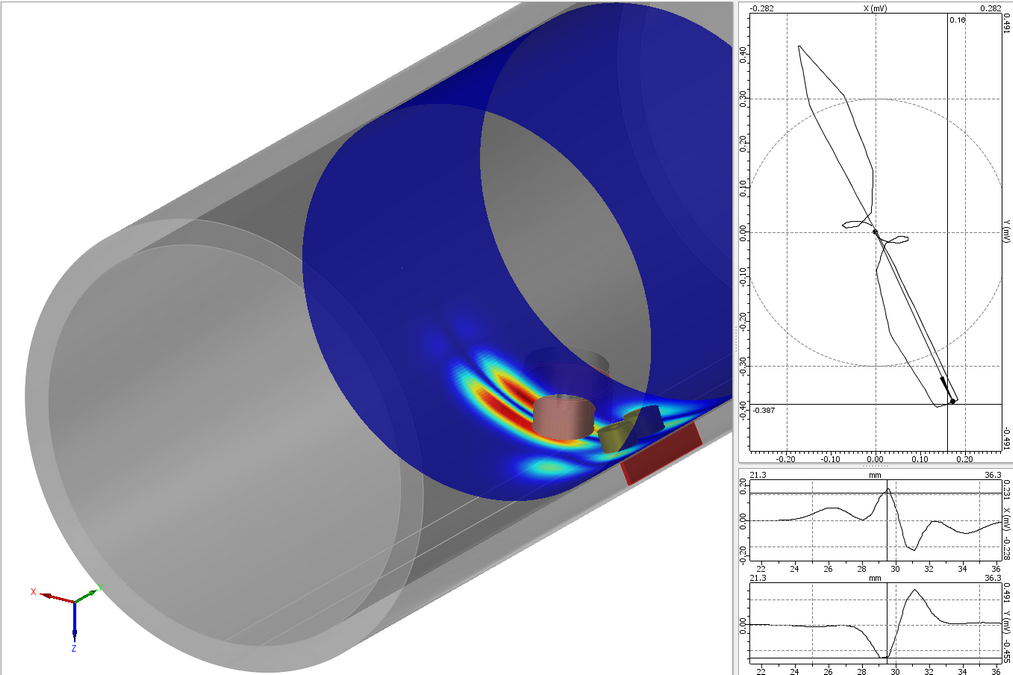

Crack Propagation Simulation: We simulate crack initiation and growth using leading tools such as Abaqus and FRANC3D, enabling us to model 3D crack fronts in complex geometries under mixed-mode loading. This allows high-fidelity prediction of crack trajectories, growth rates, and failure timelines.

Whether applied to aerospace structures, turbine components, or pressure systems, our integrated approach ensures early risk identification, robust certification pathways, and reliable service life extension.